Sing crystal diamond cutting tool

single crystal diamond tool

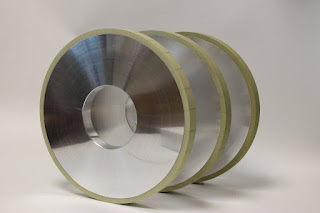

More super hard product company ground bay is a professional production and sales of diamond and CBN tools,Main products: vitrified bond diamond/CBN grinding wheel, resin bond diamond/CBN grinding wheel, electroplating and metal products, bit and polycrystalline diamond compact (PDC), polycrystalline diamond die blank, PCD PCBN cutting tools. http://www.moresuperhard.com Anna.wang@moresuperhard.com Tel/Whatsapp 008615617785923