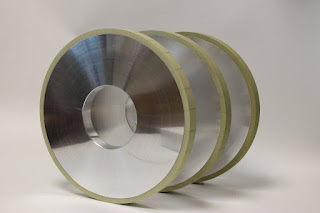

Vitrified metal mixed binder diamond grinding wheel manufacturing method

The vitrified bond diamond grinding wheel is made by mixing inorganic materials such as vitrifieds, glass or glass-vitrifieds with synthetic diamond abrasives, and then forming by high-temperature sintering after forming by powder pressing. At the sintering temperature, the binder material softens and a part of the liquid phase appears. The binder wets and wraps the diamond abrasive. A series of physical and chemical changes occur at the interface between the binder and the diamond abrasive, and the bonding agent firmly bonds the diamond abrasive. A grinding tool having a certain shape is formed. However, since the vitrified binder is brittle material and is easily broken, the diamond abrasive is peeled off, resulting in poor grinding effect of the grinding wheel, low strength and poor impact resistance. Therefore, how to realize a diamond grinding wheel with good grinding effect, high strength and good impact resistance is a technical problem to be solved in the industry.

If you need any products, do not hesitate to contact

www.moresuperhard.com

WhatsApp:+8615617785923

Anna.wang@moresuperhard.com

评论

发表评论