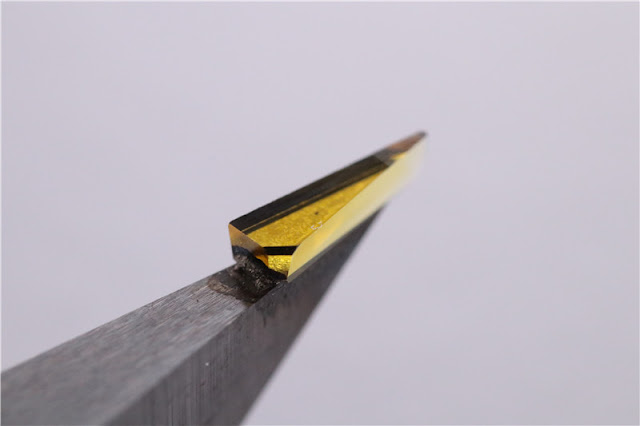

Single crystal diamond burnishing tool

The workpiece usually appears some tiny tool marks after machining. It requires one more step – “polishing” for reach superior surface finishing. However, this work slows down production efficiency a lot. “More Super Hard” launches a burnishing tool which is made of single crystal diamond now. The tools apply a certain pressure on the surface of workpiece, it generates plastic flow on the surface of workpiece, and then fill in the low through, that to achieve better surface finishing. Single crystal diamond burnishing tool not only improves the corrosion resistance and surface quality of the workpiece, but also improves the machining efficiency. 1. The hardness of single crystal diamond burnishing can reach 10,000 HV, with the characteristics of strong wear resistance and low friction coefficient, it only takes a few seconds to process the surface of the processed workpiece to the required surface accuracy. 2. The efficiency of single crystal diamond burnishing is 5-20 times of