Grinding PCD use resin or vitrified bond wheel?

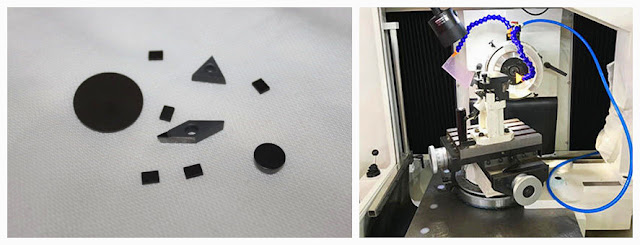

PDC is a composite material formed by

sintering diamond powder and carbide substrate under high temperature and high

pressure. Its wear ratio generally reaches 130,000 ~ 400,000, and it is

extremely difficult to process. When vitrified bonded diamond grinding wheels

are converted into 10mm working layer, each wheel can grind about 120 piece PDC , while resin grinding wheel can only grind 100~120 piece PDC.

In addition, vitrified bonded diamond wheelhas the following five advantages over resin bonded diamond wheel in PDC

processing:

1)The grinding

efficiency of vitrified grinding wheel is 3 times more than resin grinding

wheel;

2) the grinding wheel in the whole grinding

process, in addition to the first grinding wheel surface edge, no need to

repair. Resin grinding wheel must be dressed 7~12 times, otherwise grinding

parts will not start;

3)The PDC processed

by resin grinding wheel is projected into an isosceles trapezoid, one end of

the diamond layer is much larger than the other end of the matrix, and the PDC

processed by vitrified grinding wheel is projected into a rectangular shape,

the two end faces are the same size, which can be measured at a glance with a

square ruler.

Especially when the PDC "runs",

the resin grinding wheel can hardly be corrected, so the vitrified grinding

wheel will not appear this situation. This is mainly because the resin grinding

wheel has a certain elasticity, which may cause a certain yield during

grinding. However, the vitrified grinding wheel has a large elastic modulus,

good rigidity, high temperature resistance, and will not cause a knife cutting

phenomenon during grinding.

4) the workpiece smoothness is better than

resin grinding wheel. Because the resin material in the resin grinding wheel is

not resistant to high temperature, it is easy to soften at 200℃, causing

brittleness and causing edge breakage of the grinding wheel. Therefore, more

copper powder is often added in the grinding wheel to dissipate heat, while the

copper has great ductility and is easy to adhere to the PDC, making the

processed products not bright. And the vitrified grinding wheel out of the

product can almost reach the degree of mirror, is expected to rough, finishing

a process to complete;

5)A large supply

can be used. Resin grinding wheel if the use of a large amount of feed, or

grinding wheel grinding parts do not start, or grinding wheel block.

In a word, the vitrified grinding wheel is

the most suitable choice for PDC grinding due to its high grinding efficiency,

less dressing times, high workpiece size machining accuracy and high finish. However,

the problem is that the manufacturing cost of vitrified grinding wheel is

higher than that of resin grinding wheel, so the durability of the grinding

wheel must be further improved to expand the cost-performance advantage of vitrified

grinding wheel in PDC material grinding.

Have any question about grinding pcd,please contact Miss.Anna

Email: Anna.wang@moresuperhard.com,

Whtsapp: +8615617785923

评论

发表评论