Metal bond diamond glass blades

Metal bond diamond glass blades

The metal bond diamond glass blades are designed for high-speed wet cutting of sheet glass and glass tiles.

Manufactured with a continuous diamond rim and a bond suitable for cutting most glass and hard vitreous materials.

Application

Metal bond diamond glass blades

Use for glass material;Ceramic materials;Magnetic material;Semiconductor (electronic information engineering) materials;Metal materials;Cutting and slotting of brittle metal materials;

The high-precision ultra-thin cutting blade is mainly used for cutting and slotting various electronic components and precision parts in the electronic information field. It has a series of advantages such as high precision, small slitting and machining surface quality.

Metal bond diamond glass blades are mainly used for cutting and grooving of various non-metallic materials, including: semiconductor and its packaging materials, ceramic materials, magnetic materials

Other materials: crystal glass quartz hard alloy printed circuit board, etc

These metal bond diamond blades are ideally suited to most portable tile saws and the bore sizes can be altered to suit individual machines.

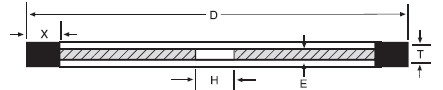

Size

PRODUCT

|

SIZE(mm)

|

LAYER HEIGH

|

Ø80 x 1.4 x 20/15mm bore

|

5mm

| |

Ø100 x 1.2 x 16mm bore

|

10mm

| |

Ø115 x 0.8 x 16mm bore

|

5mm

| |

Ø125 x 0.8 x 22.2mm bore

|

5mm

| |

Ø150 x 0.8 x 22.2mm bore

|

5mm

| |

Ø180 x 0.8 x 22.2mm bore

|

5mm

| |

Ø200 x 0.8 x 22.2mm bore

|

5mm

| |

Ø230 x 0.8 x 22.2mm bore

|

5mm

| |

Ø250 x 0.8 x 22.2mm bore

|

5mm

| |

Ø300 x 1.6mm

|

5mm

| |

Ø350 x 1.8mm

|

7.5mm

| |

Ø400 x 1.8mm

|

7.5mm

| |

Ø450 x 2.2mm

|

7.5mm

| |

Features

1. The adoption of metal material as the steel core increases the rigidity of the cutting blade and is more suitable for deep cutting.

2. Excellent wear resistance of working layer enables the tool body to have a long service life.

3. Rich types of binders meet the requirements of selecting more matched cutting blades for different processing objects.

4. The precise regulation of diamond abrasive grain and concentration makes the blade have good sharpness in the cutting process, and the cutting surface has the characteristics of high finish and good perpendicularity.

5. Precision machining means to ensure the geometric size of the blade with high accuracy.

Contact information:

Website:www.moresuperhard.com

Email:Anna.wang@moresuperhard.com

Whatsapp:+86 15617785923

评论

发表评论