Precision hole machining

MoreSuperhard materials (PCD diamond and cubic boron nitride) are known for their high hardness, but as industrial teeth, a great many of superhard materials(PCD&PCBN) related products need hole making before they can be used. Such as cutting inserts location hole, PCD diamond scribing wheels’ hole , medical device fluid orifice, water jet nozzle hole, drawing die hole and peeling tools’ hole, other PCD/PCBN wear parts’ hole etc. Our company mainly develops a new making holes’ method for PCD & PCBN materials, and adopts advanced electric processing, laser processing, ultrasonic grinding, honing and other methods to develop different processing technologies for different hole shapes. The hole diameter size can reach the accuracy range of micron meter level and the surface quality of inner hole can achieve the highest mirror effect (Ra0.25).

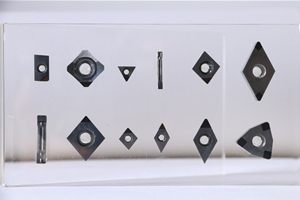

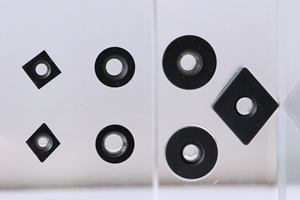

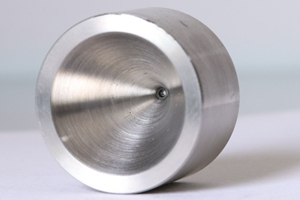

Cutting inserts hole

It is mainly for machining the locating hole of the solid or compact PCD/PCBN cutting inserts. Generally, it adopts the multi-section hole shape with cone hole joint straight hole, and it can also be customized for machining the hole type.

The cutting inserts hole | The highest accuracy | Surface roughness | hole size range | Others |

Composite blade | 0.005 | Ra0.8 | 1.5-6.0 | The taper can change |

The solid blade | 0.005 | Ra0.8 | 1.5-6.0 | The taper can change |

Special shaped hole | 0.2 | Ra0.8 | 1.5-6.0 | The hole shape can change |

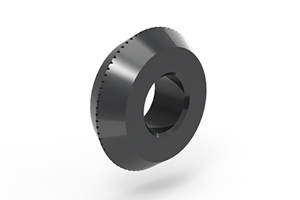

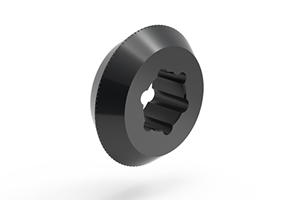

PCD diamond scribing wheels’ hole:

Mainly for the hole processing of diamond scribing wheel, diamond scribing wheel hole is the benchmark for the work of the cutter wheel, especially for the multi-wheel scribing wheels group is more demanding on the hole size precision, we use electric processing, laser processing, plus special grinding and finishing processes, the hole size precision can be up to 0.002mm, and the surface roughness up to Ra0.5.

PCD/PCBN Customized hole processing:

Hole processing range (0.05-25.0) mm

Maximum accuracy up to 0.001mm

Minimum surface roughness up to Ra0.25

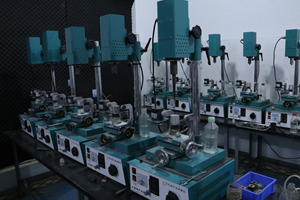

Advanced processing equipment

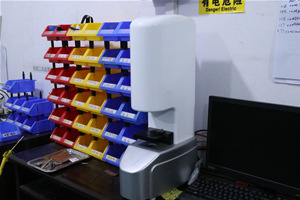

Inspection instrument

Anna.wang@moresuperhard.com

Whatsapp:+86 15617785923

www.pcdgrinding.cn

评论

发表评论